Can a light can touch insulation? Can can lights be covered with insulation? Can you blow insulation on top of can lights? Turn off the lights and leave them off for at least minutes before you touch them. If you are using incandescent.

Place a stepladder under one the lights , climb it and remove the bulb. Look for a label marked IC inside the can. Spread fiberglass batt. Up in the attic, clean the ceiling surface around each fixture, slit the cover to accommodate the electrical cable, and place the cover over the fixture. Apply the sealant around the cable and along the edge of the cover where it rests on the ceiling.

Now it will be safe to heap insulation onto that spot. Use airtight recessed lights in a cathedral ceiling to prevent heat loss, moisture problems and roof rot. The fixtures are inexpensive.

Since you mentioned your cans have holes in them, they are most definitely not IC-rated. In this particular home, a. Unscrew the bulb from each of the recessed lighting fixtures and look for the letters IC. Stuff a little insulation into the gap of the IC-rated cans, between the can and the ceiling drywall to prevent.

Purchase or construct a can light enclosure made from material with a 1-hr fire rating, that has a maximum R-value of ≤ R-0. Standard Work Specifications for Home Upgrades). Form an insulation dam to prevent insulation from contacting the lue pipe.

Cut enough aluminum from the coil to wrap around the lue plus inches. Cut slots inch deep and a few inches apart along the top and bend the tabs in. Cut slots about inches deep along the bottom and bend out the tabs. IC ratedmeans that it’s safe to have insulation directly in contact with the light, but it’s not synonymous with airtight. Notice that I said “regular” insulation, such as fiberglass or cellulose insulation, NOT spray foam insulation.

Spray foam insulation is an air seal and works a lot better than “regular” insulation does. Even when equipped with the most efficient bulbs, can lights are a major source of undetected air leakage in most homes. Recessed Can Lights And Spray Foam In Attic What is your guys suggestion for prepairing the top (attic) side of any type of can light (IC or not) before they spray foam an attic?

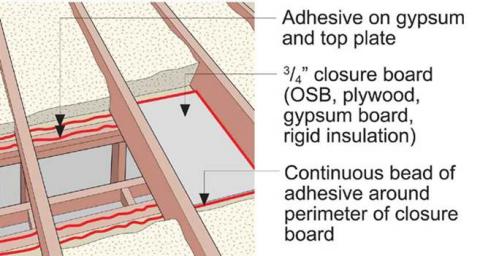

Right now with the IC cans I plan to wrap them with fiberglass batting. Insulating Around Recessed Lighting. Covering the cans Can light covers can be made out of foil faced foam boar drywall, OSB or even aluminum flashing. Or you can purchase pre made covers like these.

Make sure the cover is large enough to prevent excess heat buildup. With the advent of LED lighting, insulating downlights with clearances of 200mm can now be a thing of the past, as most LED manufacturers now recommend less clearance of insulation. On this page we cover thermal imaging comparisons of a living area with clearances and LED lighting without clearances, using a thermal downlight cover. Once the box is installed and sealed to the sheetrock, then additional insulation can be put on top. If in doubt, cut a hole in the foil.

Unless you are SURE your can lights are airtight, you should cut a hole about 12″ round in the radiant barrier foil directly above the can lights. The prospect of placing insulation around recessed lighting and other objects is much more intimidating than the actual process. You can stem the flow of air (and money) by air sealing your light fixtures from the inside with just a roll of painter’s tape, a can of spray foam insulation, and a tube of painter’s caulk.

Note that a rating of “CA” on a LED downlight means it can be abutted to insulation, but not covered. This is an important specification not often investigated to the level of detail it deserves. Covering such a downlight may result in premature failure of the light. Use Spray Foam Around Recessed Ceiling Canister Lights These lights are a prime area for heat loss, but be careful about some types of spray foam insulation around the top of ceiling light boxes.

This can trap heat and increase the danger of fire. Others, including me, believe that as long as the fixtures are IC-rated and the insulation is loose fill, air-permeable, it is safe to have the recessed housing in direct contact with the blown-in insulation. Use hardware cloth, metal flashing, or scrap plywood to create a safety gap of at least inches all around fixtures.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.