Ground ContactTreated Lumber. Protects against termites , rot and fungal decay. Must be used when lumber is less than from the.

As the names suggest, ground-contact lumber is treated to a standard to withstand rot and decay even at the point where the lumber physically touches the ground , water or leaves. Above-ground lumber is treated to a lower standard of resistance. Images via PreservedWood. Pressure treated (PT) lumber is wood that has been infused with chemical preservatives to protect the wood from rot and insects. The wood is placed in a depressurized holding tank that removes the air and replaces it with a preservative.

This process is the best way to avoid harmful rot and insects but does not prevent weathering and corrosion. The treatment process forces a waterborne preservative deep into the cellular structure of the wood providing long-term protection against rot, fungal decay and termite attack. What preservatives are used with pressure treated lumber ? Severe Weather above- ground lumber is treated with Ecolife (EL2), a unique formula that contains a built-in wood stabilizer to reduce cracking, repel water and keep wood straighter, longer. Severe Weather above ground is used for any exposed area at least six inches off the ground and is ideal for decking, fencing, arbors and trellises. The boards are rolled into giant pressurized.

Pressure - treated wood should not be used where it may come into direct or indirect contact with drinking water, except for uses involving incidental contact such as fresh water docks and bridges. Do not use pressure - treated wood in circumstances where the preservative may become a component of foo animal feed or beehives. Our treated decking and porch flooring allows you to create the perfect outdoor living space, and our treated dimensional lumber is treated to a minimum of ground contact use, making it ideal for framing and construction. Transform Your Space.

Use Lumber Liquidators. Finish Your Flooring Project. Customer Service Available. Pressure - Treated Southern Yellow Pine meets the highest grading standards for strength and appearance. Treated lumber, or pressure-treated lumber, is wood that’s been infused with preservatives to protect it from the elements including rot and insect damage.

It can be stained or painted and is frequently used as fence panels, wood fence posts, framing, wood decking and more. Is aluminum contact allowed with pressure treated lumber ? Using ground contact pressure treated lumber above ground is nothing new. The current revisions are another chapter in the decade-long struggle to find suitable substitutes for CCA, which include ACQ (alkaline copper quaternary), CA (copper azole), and µCA. Generally, fasteners and hardware made from stainless steel and hot-dipped-galvanized (HDG) steel are recommended for pressure-treated lumber.

However, lumber with the highest retention levels—such as that used in coastal and below-grade applications—should be used with stainless steel only, which is more resistant to corrosion than HDG steel. Recycled plastic lumber. Our pressure treated deck framing is treated with MCA (Micronized Copper Azole) and in our West Coast location, the wood is treated with ACQ (Alkaline Copper Quaternary). How does this benefit you? Our treated wood can be used in above ground , ground contact and fresh water immersion applications.

We sell wood and pressure treated lumber products to your specifications and in accordance with national and local regulations. Most dimensional pressure treated lumber is treated to. Larger dimensional lumber (2×and above) can be treated to. CCA but only for use in certain commercial construction applications. For any part of your deck that comes in contact with the ground or is critical to the structure’s safety, make sure you’re using wood designated for “ground contact”.

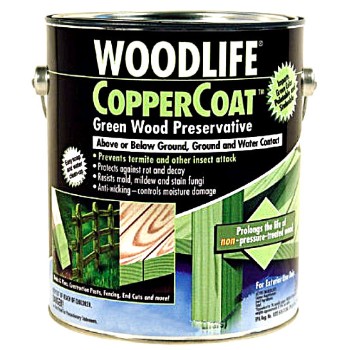

Why Does Pressure Treated Lumber Need to Be Sealed? While the chemicals in pressure treated lumber prevent rot and ward off insects, they don’t prevent moisture from seeping into. Boat docks, walkways and boardwalks are exposed to frequent wetting from waves, water level fluctuations, excessive vegetation and other factors. Surface coated means that the application of the preservative chemical is introduced by dipping, brushing or spraying the wood without being exposed to pressure.

Thoroughly coat the lumber with water sealer made for wood. Using a pump garden sprayer, spray one coat onto dry lumber. Allow the sealer to soak completely into the lumber grain, and allow two hours between coats.

Apply the second coat of sealer to the lumber with a roller or brush.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.