Build a temporary truss jig by screwing long 2×4’s to adjacent edges of the floor at degrees to each other. This way the floor acts as a giant builders square. A “ Gambrel” truss includes steel girders with steel columns available in straight leg and tapered leg versions. The Gambrel series tapered leg version is available in 24’, 30’, 40’,50’ and 60’ widths in eave heights from 8’ through 14’. With no interior walls or support posts, our engineered Gambrel Trussdesign optimizes useable upstairs interior space.

This series of diagrams shows just how the second floor lays out in each of our six different truss widths. This Gambrel Roof fits in a semicircle, and starts as the top half of an equal sided octagon. Move slider or directly enter angle to alter sweep angle of lower rafters and change the shape. Check Overhang to calculate rafter overhang equal to the lower level cut at the full rafter depth. How to build a gambrel roof?

How much does it cost to build a truss? What is the most common roof truss? What are the components of a truss? Due to the overall height the truss is manufactured as a piggyback truss to allow for transportation.

Please Note: Prices, promotions, styles and availability may vary by store and online. A regular gambrel fits inside a circumscribed semi-circle and is essentially one half of a regular octagon. Purlins joints are use slopes are fixe and the length of the top and bottom rafters (including overhang) will always be equal. In-stock at plant and ready for immediate pickup. Save design time, build time, and money with trusses built in long production runs.

Simply Search a Name and State. A “Gambrel” truss includes steel girders with steel columns available in straight leg and tapered leg versions. A gambrel has four angles, at the peak, at the wall and where the two rafters or truss chords connect.

There are three ways to calculate angles for gable trusses, which are rafters built with internal braces and installed as a unit. The Starwood Gambrel Rafter can be used to give your building the classic barn look or can be used for an economical storage solution. The gambrel truss is a kind of a supportive structure used in the roof design.

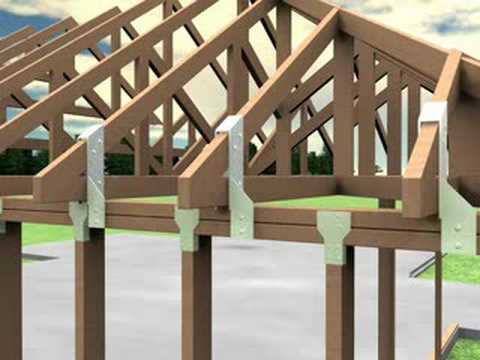

The main purpose of the truss is to provide the support to the roof transferring the weight of the roof onto the walls of the structure. The slopes of the truss are strong against complicated weather conditions. Our site-built engineered trusses are designed to transfer any lateral forces directly downward onto the side walls. This eliminates the need for upstairs post and beam supports. Because of this design, any interior walls you may wish to incorporate are non-load bearing, leaving you the freedom to create any floor plan you wish.

The roof trusses are a critical component in any structure. At Pole Barns Direct, we don’t cut corners, period. We have our own truss plant with a team of expert designers and truss builders on location. Widths available for straight leg version are 24’, 30’ and 40’ wide, with available eave heights of 8’ through 14’.

Standard truss centers will be on 10’ centers. Roof Trusses For over years, Lumber has been a leading manufacturer of metal plate connected roof trusses for some of the country’s largest single-family and commercial builders. We utilize state-of-the-art technology – the latest design software, computerized saws, and specialized jigging equipment, all of which are designed to.

Neem gerust contact met ons op voor advies, uitleg of een offerte op maat.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.