Fencing For Any Look. Create Memories All Summer Long. Save $0or more by doing it yourself. Why to use cellulose insulation? What is cellulose attic insulation? Can cellulose be recycled?

Some of the most common materials used for cellulose insulation include cardboar corncob, cotton,. First, you’ll want to seal all air leaks where anything comes through the bottom or top of the. The fibers are treated with some safe chemicals, which make it fire-resistant and resistant to vermin. Fill hopper on the insulation blower with cellulose insulation.

Force the nozzle on end of blower hose into the lower hole in wall. Turn on blower to force insulation up into space between the two studs. Use a rag to plug upper hole, if necessary, to prevent insulation from blowing out. Dry cellulose insulation is made from recycle shredded newspaper, which has been chemically treated to be fire-resistant.

Blown-in insulation refers to loose insulation made of fiberglass, cellulose or foam that is literally blown into place with hose-type equipment. It is used to fill empty spaces in the structural part of a house to slow down the transmission of heat or cold. Cellulose insulation is a type of wood- or paper-based product. Corey Binford 375views.

Attic Air Sealing and Insulation How To - Duration: 8:03. During the manufacturing process, this paper is broken down into its most basic element, cellular fibers from a tree. Brands: Some blown-in cellulose insulation brands include GreenFiber, Applegate, and Nu-Wool. Blow-In Blanket Insulation Blow-In Blanket system (BIBS) is the trademarked name for a patented new-construction method of insulating walls with blower-injected insulation that can be used for either open or closed walls.

Dense packed cellulose insulation at 3. R-factor in excess of 4. So if your house was built before insulating walls became standar you can potentially save a great deal of energy by insulating. When comparing blown-in insulation , both fiberglass and cellulose are nearly identical in price, both costing around $0. Fiberglass batts, however, are less expensive, costing on average $0. Both can be added to uninsulated attics or layered over existing material.

Free 2-day Shipping On Millions of Items. Thermal Insulation for pipes, ducts and equipment. Dry blown (loose-fill or dense pack) and spray applied (moisture-added.) Dry blown is an option for homeowners interested in a do-it-yourself ( DIY ) cellulose insulation installation. The moisture-added technique requires special equipment and can only be done by trained installers.

Install cellulose insulation by blowing it into the cavities in the attic with an blower machine. It is possible to install some types of cellulose insulation as DIY projects. However, CIMA recommends using a professional insulation contractor for any type of installation to achieve the best and maximum energy savings.

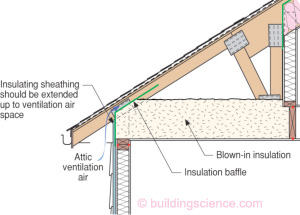

It’s important to select a contractor with experience installing cellulose. Blow the specified amount of insulation evenly throughout the attic to achieve the correct R-value. The packaging will have the amount of insulation required to achieve the stated R-value. There should not be any reason to remove the previous insulation but be sure to check what you are going to be insulating before starting the process.

Each insulation is only as good as its weakest point. While not dangerous, cellulose insulation can be an irritant if it gets on your skin or if you inhale it. Wear pants, boots, long-sleeved shirt, gloves, a hat, eye protection and a respirator. At the bottom of this post we have a link to every post in this series if you want to check out the whole shebang :) After days of prep work and hours of sweating, it was finally time to do the most fun and satisfying part of the process- blowing the insulation ! Each bag of fiberglass insulation will cover approximately square feet of attic space to a depth of inches ( cellulose insulation covers half as much). Ten inches of blown insulation provides an insulating value of approximately R-(1-inch of fiberglass provides about R- while 1-inch of cellulose is approximately R-3).

Greenfiber blown-in cellulose insulation This 30-lb.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.